charpy impact test data sets to download|charpy impact test sample : commercial The machine receives test specimens from a multi-specimen magazine, reads the . Resultado da Betty Casino Ontario: Overview of Live Casino & Betting Review Last Updated: January 21, 2024 Overall Rating: 4.5 /5. Betty Casino, operated by Betty Gaming CA, Ltd is known for providing safe and fair slot games. Their eCOGRA certification further solidifies the fairness of their games.

{plog:ftitle_list}

7 de fev. de 2022 · Displaying a List with a React Native FlatList. The FlatList component requires two props: data and renderItem.A data prop takes an array of data that needs to be rendered, and renderItem defines a function that takes data via parameters and returns a formatted component to be displayed on the screen.. The basic code to implement .

charpy impact test sample

Charpy Data Fitting. Impact tests are performed to measure the response of a material to dynamic loading. Many materials exhibit a transition in fracture mode which is a strong .The open tank which contains the test specimens is available in 11-liter or .

The machine receives test specimens from a multi-specimen magazine, reads the .

polarimeter tube temperature

MP Machinery and Testing manufactures the most accurate Charpy impact test .Precision tongs are an essential part of the Charpy impact test and incorrectly .MPM has developed a fully automated Charpy impact test machine that can be .MP Machinery and Testing manufactures the most accurate Charpy impact test .

Pressure Vessel Manufacture - Charpy Data Fitting — MP Machinery and .Nuclear News - Charpy Data Fitting — MP Machinery and Testing, LLC

Experimental Services - Charpy Data Fitting — MP Machinery and Testing, LLCThe specimen transfer system transfers the test specimens one at a time to the test .

The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .Before valid Charpy measurements can be made in the laboratory, the machine needs to pass. both direct and indirect verification tests as specified in ASTM E 23 [1]. Even if a Charpy .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The algorithms are described in detail and demonstrated using a data set of 12 Charpy test results (shear area and absorbed energy) from one API-5L grade X52 pipe with 4.5 mm thick .

In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .The Charpy impact test provides characteristic values for the impact strength at high strain rates in the form of a surface area related value. The test measures the impact energy in relation to the fracture surface in joules.

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

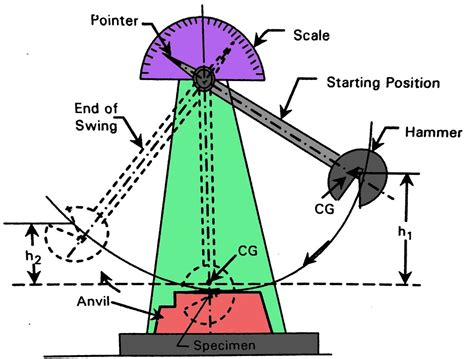

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability . Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .The algorithms are described in detail and demonstrated using a data set of 12 Charpy test results (shear area and absorbed energy) from one API-5L grade X52 pipe with 4.5 mm thick Charpy bars.What is an impact testing machine? An impact testing machine is used to determine the resistance of a material or component to a rapid load under varying temperature conditions. Depending on the material to be tested, the end-use application requirements, and the preferred type of test data, a choice is made between pendulum impact testers and .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Current trends will likely shape the future of the industry, which is set to continue to show. . Please confirm any data provided with . Set up Sample: The sample must then be carefully placed into the testing machine. The sample should be handled with tongs to ensure that no body heat is transferred into the sample or to prevent injuries with very cold or very hot samples. . Qualitative data is non-numerical observational data. In the Charpy impact test, this refers to the .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a . Download Citation | Data mining and modelling of Charpy impact energy for alloy steels using fuzzy rough sets | When considering data-driven modelling, uncertainties, errors and inconsistencies in .

Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports. NIST certifies its reference specimens using three of the Boulder lab’s multiple Charpy machines, and ships out about 2,000 sets of five specimens per year. Because impact toughness changes with temperature, NIST requires its specimens to be tested at -40 ˚C.

The algorithms are described in detail and demonstrated using a data set of 12 Charpy test results (shear area and absorbed energy) from one API-5L grade X52 pipe with 4.5 mm thick Charpy bars. History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

Download: Download high-res image (192KB) Download: Download full . with the lower shelf value set to a constant value of 2 J for all data sets in the form (2) . Conventional Charpy-V notch impact testing was also conducted on the test welds to characterize their ductile-to-brittle transition and to correlate the CVN energy with fracture .

Splett JD, McCowan CN, Iyer H and Wang C Computing Uncertainty for Charpy Impact Machine Test Results NIST-SP 960-18 (2008) Siewert TA Evaluation Specimens for Izod Impact Machines (SRM 2115): Report of Analysis NIST SP 260-164 (2007) McCowan CN and Splett JD Analysis of Charpy Impact Verification Data: 1993-2003 Journal of ASTM International . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for .Charpy Impact Test - Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It . 1. Introduction. Instrumented impact testing is often considered to be a relatively recent technical development of Charpy testing, even though the earliest known paper dealing with force measurements during an impact test [] actually predates the first pendulum machine publication [] by one year.In actual fact, instrumented Charpy testing started to gain .

polarimeter tubes

Charpy impact test's ability to detect an intentionally introduced defect in a tested sample is studied, involving exploitation of force-displacement data recorded during the test on reduced-size samples. . The diaphragm was set to “depth” (aperture diameter of 20 μm) with an accelerating voltage of 15 kV, a probe current of 80 pA, and a .

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantThe NIST software s tested on Charpy i three absorbed energy . Two datasets datasets correspond to actual impact test results performed on various pipeline steels, while the third is a simulated dataset generated from predetermined model parameters. These datasets allow a thorough demonstration of the NIST software. A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture toughness . Abstract The NIST Charpy Machine Verification Program supplies ASTM E23 certified Charpy reference specimens to customers all over the world since 1989, when the program was transferred from the US Army at Watertown Arsenal, Massachusetts.

LAB 2: CHARPY IMPACT TEST 1 1. Introduction The impact test is a high-strain rate assessment of the material properties where a hammer attached to an arm will drop in a pendulum motion and impact the test specimen. The critical part of this experiment is the samples which will be prefabricated into the Charpy V-notch design which is a 55x10x10 mm .

Download Citation | Data Mining and Modelling of Charpy Impact Energy for Alloy Steels Using Fuzzy Rough Sets | When considering data-driven modelling, uncertainties, errors and inconsistencies in .impact is applied to the face directly behind the notch using the blow from a swinging pendulum hammer. The impact testing machine calculates the energy absorbed, which can be converted to impact strength using the following equation: impact strength = energy absorbed area under the .

Resultado da Όλες οι ειδήσεις για το Ποδόσφαιρο στο sport24. Μείνετε ενημερωμένοι για τις αθλητικές ειδήσεις γύρω από το ποδόσφαιρο και νέα για τα πιο δημοφιλή πρωτα.

charpy impact test data sets to download|charpy impact test sample